Wedge wire screens

Wedge wire screens

Drainage and filtration

The screen surfaces are made of wedge wire that provides unique permeability properties. They are used in drainage, filtration, desludging and screening.

The screen surface is fixed into technological machines (screening machines, dehydration troughs and slides, drainage bottoms, malt kilns, fermentation reactors and other) in various ways. It is usually screwed or wedged to the machine frames.

FIELD OF APPLICATION

Sandpits, mines, food industry, sewage treatment plants, sugar industry, breweries, malt houses.

DIMENSIONS SUPPLIED

Custom-made. Slot size supplied from 0.05 mm to 10 mm.

MATERIALS SUPPLIED

Stainless steel in various quality

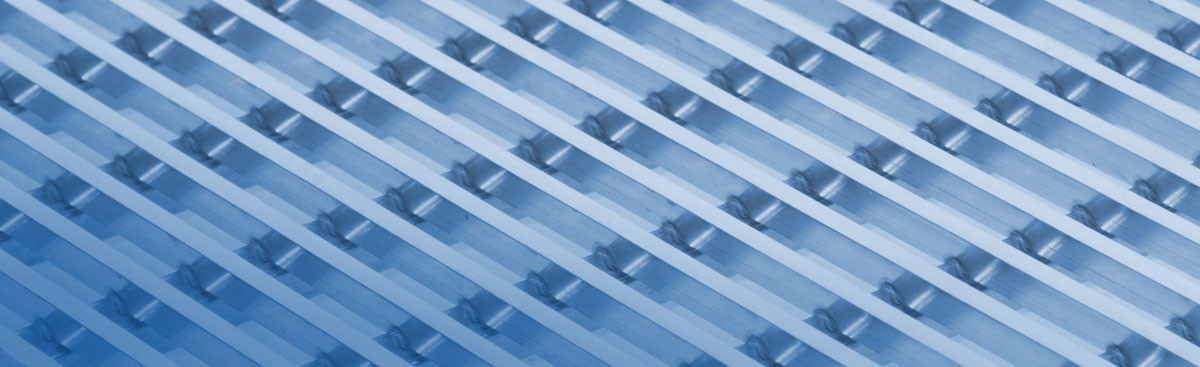

WELDED WEDGE WIRE SCREENS

They consist of wedge shaped wires that are welded on crosswise profiled wires. They are characterized by a high accuracy of a slot width, perfectly smooth working surface and their stable construction. They can be reinforced. Depending on the nature and abrasiveness of the screened material, it is possible to change the shape of the wedge wire and thus affect the lifetime of the screen. Welded wedge wire screens can be produced for certain applications (paper industry) with wedge wires welded to beams at a certain angle.

- Perfectly smooth work surface

- Long lifetime

- Possibility to bend to smaller diameters

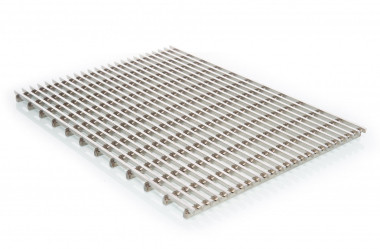

LOOP WEDGE WIRE SCREENS

They consist of wedge-shaped wires with loop meshes on reinforcing bars which are at the ends finished with a thread and nut, possibly riveted and welded to the side beams or around the perimeter into the support frame. Screen surfaces without reinforcement can be additionally shaped.

- Robust construction resistant to a high load

- Accurate slot width

- Long lifetime

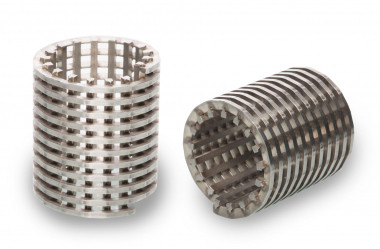

SLOTTED CYLINDERS

The shape variability of the loop profile wires as well as the welded profile wires makes it possible to produce various slotted cylinders, baskets and other specially shaped slotted surfaces, which are irreplaceable in the processes of dewatering, thickening, filtration and screening.

- Sturdy construction

- High accuracy of slots in an axial and radial direction

- Indoor (FITO) or outdoor work area (FOTI)