Technical cloths

Technical cloths

Technical cloths are fine screens, which in their finish resemble fabric.

Technical cloths are used in various industries (chemical, food, glass, construction) for example as sorting and filtration screens, single or multi-layer filters for plastics processing, protective equipment, reinforcement, supports, etc. Nowadays, the use of cloths in architecture is being increasingly promoted.

We supply technical cloths in rolls with a standard width of 1 m or they can be cut to the required size. The length of the roll is usually 30 m.

COMMONLY USED MATERALS AND THEIR FINISH

(according to DIN ISO)

- 1.4301

- 1.4401

- 1.4404

- 1.4541

- 1.4841

- 1.4310

- black steel

- galvanized steel

- non-ferrous metals

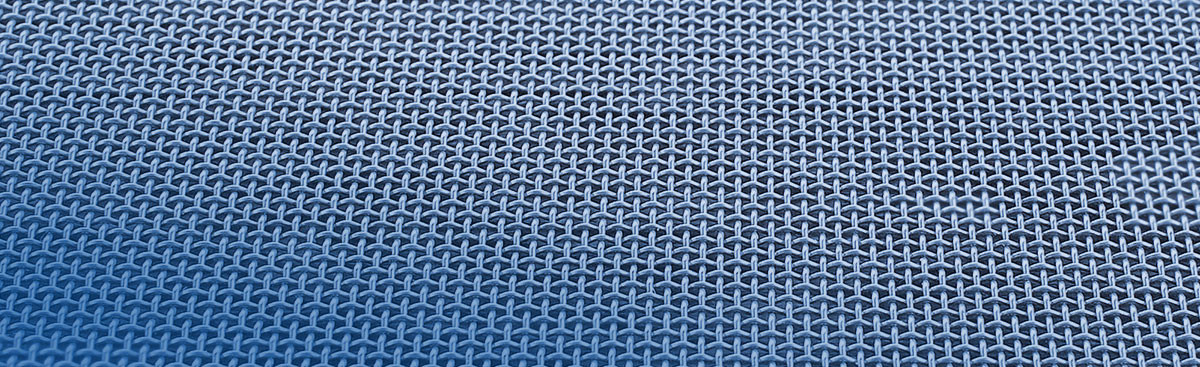

WITH A SMOOTH WEAVE

This is the most common way of technical cloths weaving. Each wire is bent either in the warp or weft, and this arrangement alternates regularly.

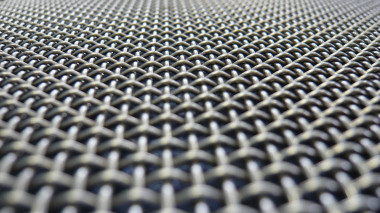

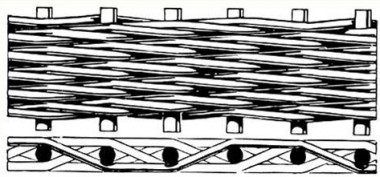

WITH A TWILLED WEAVE

Twilled weave

Two wires are always bent with a consequential overlap of one wire (see figure). This type of weave is chosen especially when the wire is too thick compared to the mesh size or where the cloth is too fine and the bent wire does not keep in the weave.

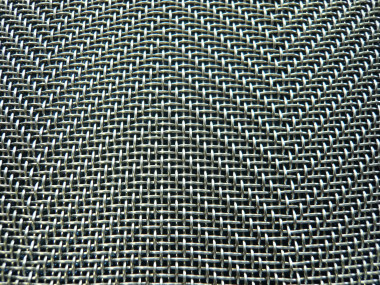

Pointed or alternated twill

This type of weaving is used when it is necessary to avoid possible transverse displacements. Due to frequently occurring differences in the mesh, it is mainly used for making various linings and very rarely in filters or screens. (see figure)

FILTRATION CLOTHS

SMOOTH WEAVE

The weft wires are so close together that the "zero mesh" arises. The warp wires are thicker than the weft wires. Good flow capacity through the holes of the same size and easy cleaning are the main advantages of this type of cloth.

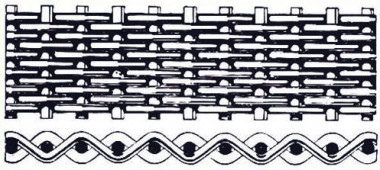

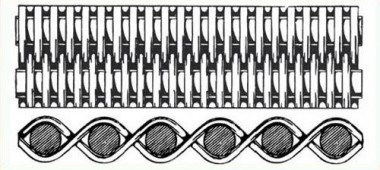

TWILLED WEAVE (LIGHT IMPERVIOUS)

The weft wires are placed close to each other in the twill weave. One weft wire always lies above and another wire below the warp wire. Compared to a smooth weave, there is twice the number of wires (see figure).

ARMOURED WEAVE OR REVERSED BELT

Unlike the belts of weave, most wires are placed in the warp system. Therefore, the weft wires are considerably thicker than warp wires. This special design is characterized by a high stability and guarantees a good flow capacity.

OPEN FILTRATION WEAVE

This filtration cloth is made in the same way as conventional belts. The weft wires are not laid so close next to each other, but at a certain distance, therefore the cloth flow capacity is increased. The disadvantage is less regular mesh. The open filtration cloth is produced:

- in a smooth weave

- in a twilled weave

TWILLED ARMOURED WEAVE

It is a technical cloth, where the combination of twilled weave and placement of most wires in the warp makes it possible to use in extremely demanding environments due to its high stability and strength.