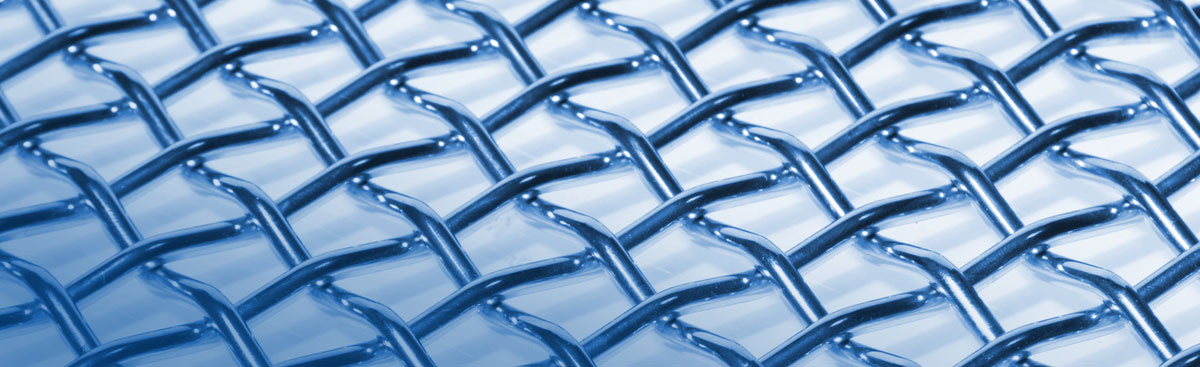

Wire screens with rectangular mesh

Wire screens with rectangular mesh

The most open wire screens

Wire screens are widely used in many areas of industry where they are used for screening, dewatering or drying. Their big advantage is the maximum possible free area and stability of the mesh, which ensure exceptional screening performance while maintaining the sharpness of screening.

- Sharpness of screening

- Available with or without folds

- Suitable for dry and wet screening

Field of application

Quarries, gravel pits, mines, recycling, industry

DIMENSIONS SUPPLIED

Can be supplied in rolls or stock dimensions, with or without tensioning fold. The screens with folds are custom-made.

MATERIALS SUPPLIED

Spring steel: STN 12050, DIN 17223 (also available in plain steel STN 11 373)

Stainless steel materials: DIN 1.4301, 1.4310, 1.4541 ...

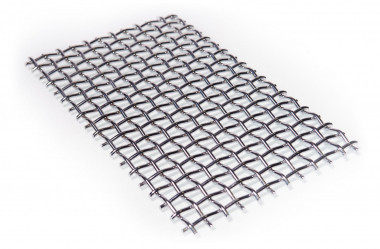

SINGLE CRIMP WIRE SCREENS

It is the most widespread sorting screen, characterized by two-way crimping of wires at the crossing point. We supply these screens with mesh size up to 150 mm and the wire thickness up to 12.50 mm. We can also supply them in rolls, up to a maximum of 3.50 mm wire thickness.

- Suitable for smaller fractions

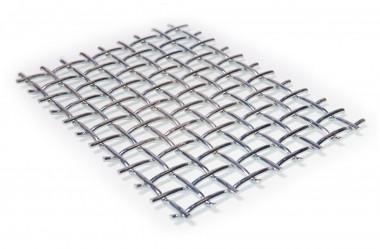

DOUBLE CRIMP WIRE SCREENS

In terms of use, it is the same type of the screen as a single crimp screen. Due to the larger mesh, these screens have an additional double crimp on each wire at the crossing point, but also before and after it, to ensure a stronger bond. This ensures the strength of the entire screen, longer lifetime and especially the stable mesh size.

These screens are available with a mesh size up to 150 mm and a wire thickness up to 12.50 mm. We can also supply them in rolls, up to a maximum of 3.50 mm wire thickness.

- Suitable for larger fractions

- Stable mesh

ONE-SIDE SMOOTH WIRE SCREENS

It is a woven screen with a stronger binding, characterized by the fact that, compared to conventional screens, all the crimps are only on one side of the wire. Therefore one side of the screen remains smooth while the other is wavy. Usually the upper side is the active one. It can also be used as a support screen for technical cloths. These screens are available with a mesh size up to 150 mm and a wire thickness up to 12.50 mm. We can also supply them in rolls up to a maximum of 3.50 mm wire thickness.

- Suitable for larger fractions

- Longer lifetime

PRESSURE WELDED WIRE SCREENS

They are used for screening larger fractions of loose materials with a requirement for long lifetime, durability and use of a thicker wire, which is not possible to weave. Wires made of wear-resistant manganese steel are pressure welded at the intersection, which ensures precise mesh size and extremely strong construction. We supply these screens with mesh size up to 150 mm and wire thickness up to 20 mm.

- Suitable for larger fractions

- Long lifetime

- Ideal landing screen